Synthesis gas and wood gas

What is synthesis gas?

Synthesis gas (syngas) is a combustible gas mixture consisting mainly of hydrogen (H₂) and carbon monoxide (CO). It can also contain varying amounts of carbon dioxide (CO₂), methane (CH₄), nitrogen (N₂) and other gases, depending on the production method.

Synthesis gases are produced by the thermal conversion of carbonaceous materials such as coal, biomass or plastic waste in a low-oxygen environment or an environment with a low oxidizing effect.

Common processes for the production of synthesis gases are classic gasification (e.g. of coal or biomass) or the reforming of natural gas (with steam, oxygen or CO₂).

Synthesis gases are used for the production of chemical products such as methanol, ammonia, Fischer-Tropsch fuels (synthetic fuels), electricity and heat generation or as a raw material for hydrogen production.

Wood gas is a synthesis gas

Wood gas is a special synthesis gas that is obtained by gasifying wood or other woody biomass. It is a combustible gas mixture that played a role in historical times of emergency (e.g. in wood gas-powered vehicles during the Second World War) and is now taking on a relevant role in the course of the energy transition/renewable energies and the level of technical development that has now been achieved.

Wood gas is a combustible gas mixture produced by the thermochemical gasification of wood in the absence of oxygen. It mainly consists of carbon monoxide (CO), hydrogen (H₂), methane (CH₄), nitrogen (N₂) and carbon dioxide (CO₂).

Wood gas is produced in a wood gasifier at temperatures of approx. 800-1,400 °C. Wood gasification takes place under a controlled lack of oxygen (pyrolysis, oxidation and reduction). The wood gas has specific physical, chemical and energetic properties that make it suitable for certain applications (e.g. electricity generation, heat generation, production of chemical raw materials).

Picture: Bundesarchiv Bild 183-V00670A, Berlin 1946, Car with wood gas drive.

Creative Commons Attribution. Via Wikimedia Commons

Extraction of wood gas

Wood gas is produced by gasifying wood, a thermochemical process in which wood is converted into a combustible gas mixture at high temperatures with a limited supply of oxygen. This gas mixture consists mainly of carbon monoxide (CO), hydrogen (H₂) and methane (CH₄) as well as carbon dioxide (CO₂) and nitrogen (N₂). Depending on the production process, the wood gas contains small to medium quantities of tar substances in a gaseous state.

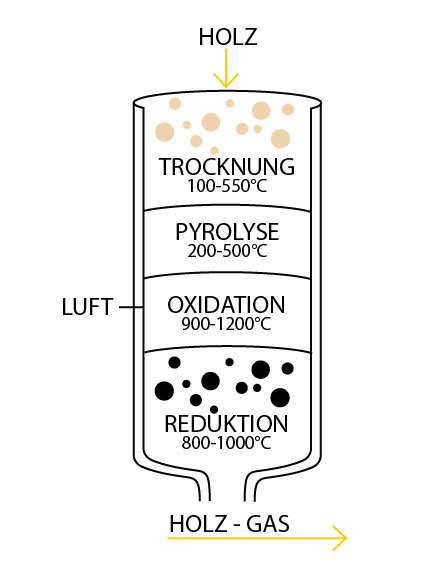

The process takes place in several steps:

Filling the gasifier: Wood in the form of wood chips or pellets is filled into the gasifier from above.

Drying (100-150 °C): The wood is first dried using the waste heat from the lower part of the reactor. The water it contains evaporates in the process. This is necessary so that the actual gasification process can run efficiently.

Pyrolysis (200-500 °C): The dried wood decomposes under heat into solid components (charcoal), gases and volatile organic substances (tars and oils). Products: Synthesis gas, tar, charcoal

Oxidation (800-1400 °C): A controlled supply of air (or oxygen) is used to burn off some of the pyrolysis products. The resulting heat drives the pyrolysis and reduction reactions. Reactions:

- C + O₂ → CO₂ H₂ + ½ O₂ → H₂O

Reduction (800-1000 °C): In the hot zone, the remaining charcoal reacts with CO₂ and H₂O, among others, to form combustible wood gas. Reactions:

- C + CO₂ → 2CO

- C + H₂O → CO + H₂

- C + 2 H₂O → CO₂ + 2 H₂

Gas purification and utilization: The hot wood gas is discharged from the reactor and purified in filter systems (tar, dust and any condensates are removed) and then used, for example, in a CHP unit to generate electricity.

What types of wood gasifiers are there?

Fixed-bed gasifier (counterflow gasifier)

Compact, very efficient, but often high tar content in the wood gas.

Fixed-bed gasifier (direct current gasifier)

Compact, efficient, good for small and medium-sized systems, low tar content in the wood gas.

Fluidized bed gasifier

Higher mixing, suitable for larger systems, lower tar content in the wood gas.

Entrained-flow gasifier

High temperatures, fast reactions, especially for industrial applications.

Applications of wood gas

Heat generation

Can be used directly in a burner or boiler. Use in local heating networks, drying systems, greenhouses, etc. extremely easy to use, as no extensive gas cleaning is required.

Electric power generation

Wood gas drives a gas engine or a gas turbine to generate green electricity. Additional heat utilization is possible in combined heat and power plants (CHP). Overall efficiency with combined heat and power generation: >80 %. Ideal for decentralized energy supply, e.g. in municipalities, trade and industry.

Industrial process heat

Use in high-temperature processes (e.g. metal processing, ceramics production, drying) and as a substitute for fossil fuels in certain industrial plants.

Vehicle drive (historical and experimental)

In the past (e.g. during the Second World War), so-called wood gas cars were in use. Today they are more of historical or experimental interest, the applications are complex and difficult to regulate.

Chemical processing (synthesis)

Wood gas contains CO and H₂ and can be used as synthesis gasfor the production of methanol, ammonia, Fischer-Tropsch fuels (synthetic diesel, kerosene).

Synthetic natural gas (SNG)

Pioneering for the bioeconomy and green chemistry. https://www.ecoloop.eu/anwendungen/

The advantages of wood gas are manifold

- Renewable and climate-friendly

Wood is a renewable raw material. When managed sustainably, wood gas is almost CO₂-neutral, as CO₂ is bound during the growth of the wood.

- Utilization of residual materials

Wood waste (residual fractions from forestry, sawmill waste wood, etc.), bark and other biogenic residues can also be gasified – thus avoiding waste and creating regional added value.

- Diverse applications

Wood gas can be used for electricity, heat or fuel. Particularly efficiently via powerheat–coupling (CHP).

- Decentralized energy supply

Ideal for regions with a lot of forest or residual wood – enables regional independence from fossil fuels.

- Technically proven

Wood gasifiers and wood gas CHP units are proven technologies that are available on an industrial scale.

- Contribution to the energy transition

As part of a bioenergy mix, wood gas can replace fossil fuels in rural areas.

Limits to the use of wood gas

- Low energy content

Wood gas contains a lot of nitrogen and CO₂which lowers the calorific value below that of natural gas (approx. 4-6 MJ/m³).

Solution contribution VEE:

Technologically advanced, industry-standard systems with high efficiency.

- Tar substances and condensates

Raw wood gas contains tarsubstances and dust, which must be carefully filtered. So that Motors or turbines not damagedbe damaged, a gas cleaning is required.

Solution contribution VEE:

High temperatures in the gas generator and in the filter systems prevent the formation of tar and condensates within the process.

- Safety risks due to toxic substances

Wood gas contains carbon monoxide (CO), which is highly toxic and odorless. Strict safety precautions are necessary, especially in enclosed spaces.

Solution contribution VEE:

Integrated CO monitoring in the installation rooms, high-quality and durable sealing systems to prevent gas leaks, standard-compliant planning, design and operation in accordance with the applicable DIN, ÖNORM and safety regulations.

- Fluctuating gas quality

The composition of the wood gas varies depending on the type of wood, moisture and operating conditions. The Regulation and control complex.

Solution contribution VEE:

Complete solution in plant construction and plant control, from wood chip drying to residue discharge, the processes are monitored with sensors and the plants are regulated.

- Investment risk

Thee economic efficiency of wood gas systems depends inter alia on subsidies, the price of wood, CO₂-certificate price and the income from the sale of heat and electricity (feed-in tariff or savings from own use) from.

Solution contribution VEE:

The VEE Wood Gas Systems offer a good overall economic concept with very high power density, low space requirements and high system availability (> 8,000 h/y)

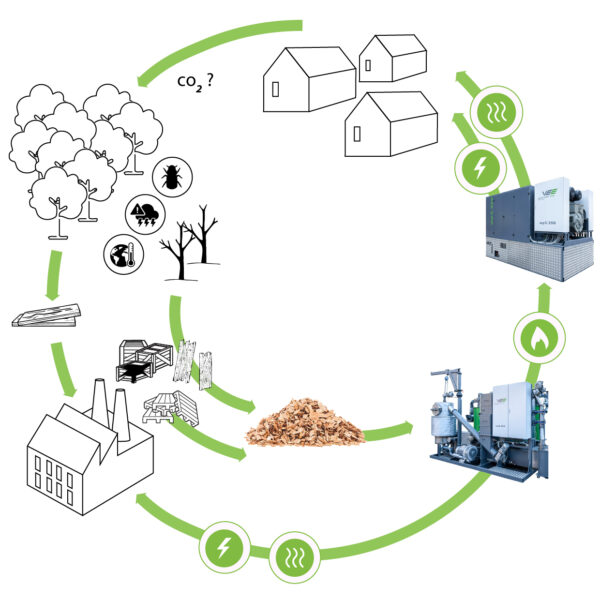

Wood gas in a closed CO2 cycle

Wood gas is sustainable

Renewable raw material

Wood is renewable, provided it comes from sustainably managed forests. The use of high-quality wood for energy production (instead of as construction timber, etc.) does not make ecological or economic sense.

If sawmill waste wood and waste fractions from forestry are used responsibly, for example, the CO₂ cycle remains closed: The CO₂ produced during combustion was previously bound by the tree. Even forests that have been damaged, e.g. by bark beetles, can be put to good use.

High efficiency with combined heat and power (CHP)

Wood gas is simultaneously converted into electricity and heat in combined heat and power plants (CHP). A total utilization rate of over 80 % is possible with good plant technology.

Regional cycles possible

Wood gas plants can be operated decentrally, which reduces transport emissions and strengthens the regional economy and resilience.

Use of residual and waste wood

Gasification technology can use non-sawable wood, such as forest residues or wood chips, to generate energy, i.e. it can utilize biogenic waste instead of disposing of it.

Climate change is causing significantly more damaged wood (storms, bark beetles, diseases and fungal infestation, etc.) in many regions than in previous decades. The use of wood gas has a much better environmental balance than if the damaged wood rots and CO₂ is released unused into the atmosphere.